FAX-38 Powder Metallurgy Steel: Modern Performance in Knives

In the world of knife steels, new innovations are constantly emerging, pushing the boundaries of performance. FAX-38 is one such modern material: a powder metallurgy steel that offers significant advantages over traditional manufacturing processes. This steel combines exceptional wear resistance, high hardness, and good edge retention, making it a favorite among manufacturers of premium knives.

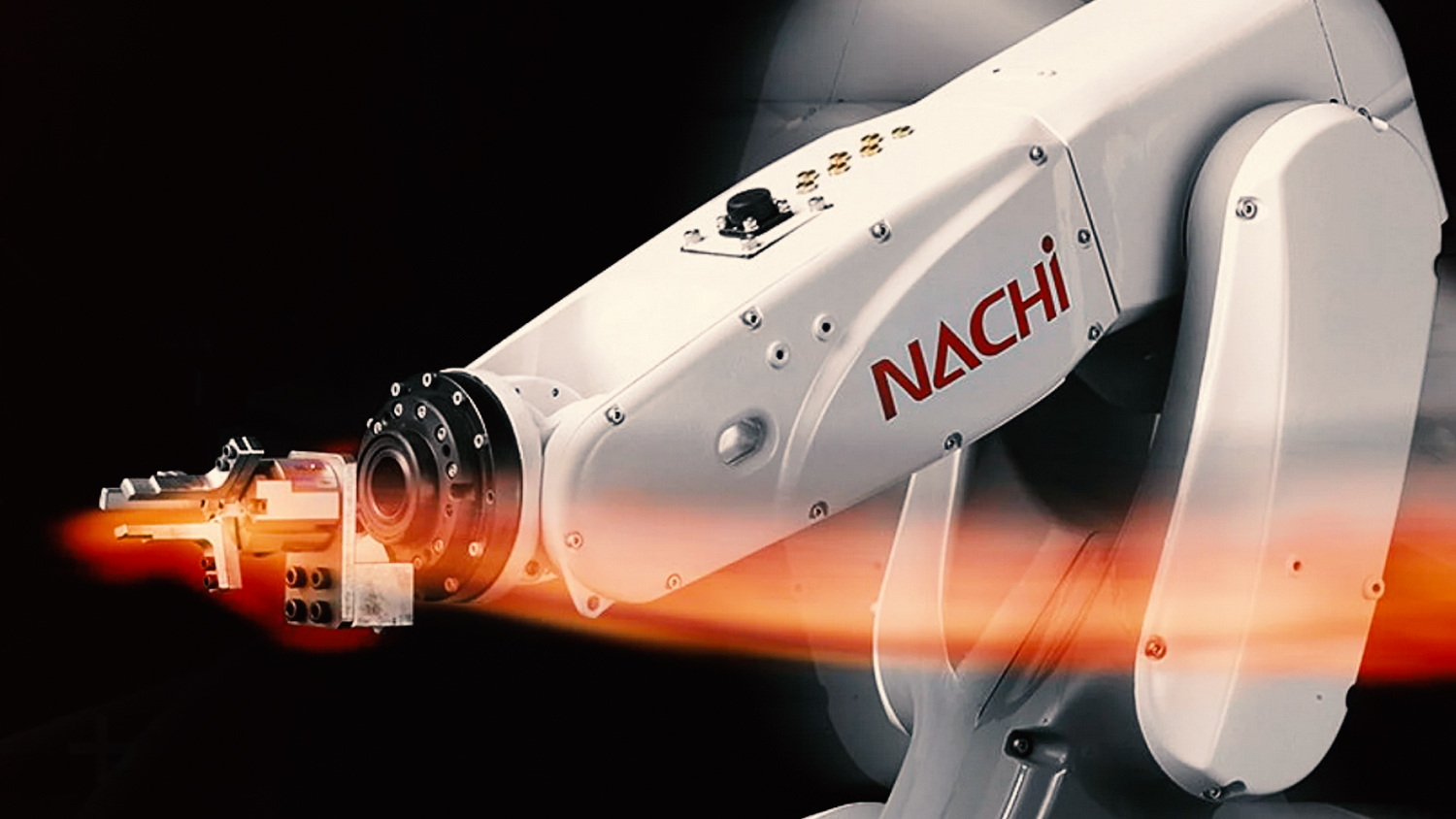

Manufacturer: Nachi-Fujikoshi Corp.

FAX-38 steel is manufactured by the Japanese NACHI-FUJIKOSHI CORP., a long-established and widely recognized industrial company active in diverse fields. Nachi-Fujikoshi is not only involved in steel production, but its portfolio is extremely diversified, including cutting tools, robots, bearings, hydraulic equipment, machine tools, automotive hydraulic systems, and thermal insulation materials (Thermotech).

The company's history and philosophy are built on precision and innovation, allowing them to play a leading role in the special steels market. Nachi-Fujikoshi offers a very wide range of special steels, including high-speed steels, alloy tool steels, bearing steels, martensitic stainless steels, and special materials such as the Micron Hard Cermet NAX Series for Milling, the EXEO series: functional component materials, the DURO series: tool steels, and the PROVA series: corrosion-resistant steels for mirror plastic injection molding. This extensive expertise and continuous research and development guarantee that materials like FAX-38 meet the highest quality and performance requirements.

The History and Advantages of Powder Metallurgy

FAX-38 is a relatively newer generation steel manufactured using the advanced Powder Metallurgy (PM) process. Unlike traditional steel production, where steel is cast and rolled from a liquid state, the powder metallurgy process involves producing steel in the form of metal powder. This powder is compacted at extremely high pressure and temperature (sintering) to create a homogeneous material with a fine grain structure.

This process offers several key advantages:

- More Homogeneous Structure: There's no segregation (uneven distribution of alloying elements), which can occur during traditional casting. This results in more consistent properties along the entire length of the blade.

- Finer Carbides: In powder metallurgy, the hard carbides (responsible for edge retention) are much finer and more evenly distributed. This improves the steel's toughness without compromising wear resistance.

- Higher Alloying Possibilities: Powder metallurgy also allows for the production of steels that would contain too many alloying elements through traditional methods, thus becoming too brittle. FAX-38 benefits from this capability.

The development of FAX-38 aimed to create a steel capable of withstanding high stress while providing excellent edge retention and corrosion resistance. Although not as widespread as AUS-8A or the more popular S30V, it's increasingly recognized in the quality knife market. This steel belongs to the premium segment, and while Satake currently focuses mainly on easy-to-maintain blades for everyday use in its kitchen knives, our offerings also include chef's knives made from FAX-38.

Composition

The chemical composition of FAX-38 is carefully balanced to maximize performance across various properties. It typically contains the following elements:

- Carbon (C): Approx. 1.35% This high carbon content is fundamental to FAX-38's exceptional hardness and edge retention. Carbon forms hard carbides with other alloying elements.

- Chromium (Cr): Approx. 15.00% The high chromium content ensures excellent corrosion resistance, making FAX-38 a stainless steel. This is crucial for knife maintenance and longevity, especially in a kitchen environment.

- Molybdenum (Mo): Approx. 2.00% Molybdenum increases the steel's toughness, wear resistance, and improves corrosion resistance, particularly against chlorides. It also contributes to a finer carbide structure.

- Vanadium (V): Approx. 0.80% Vanadium is key for wear resistance and edge retention. It forms extremely hard vanadium carbides, which are even harder than the chromium carbides found in conventional steels. This ensures FAX-38's long-term sharpness.

- Cobalt (Co): Approx. 1.50% Cobalt increases the steel's heat resistance and hardness, especially at high temperatures. It also improves the secondary hardening response, allowing for better heat treatment results.

- Manganese (Mn): Approx. 0.50% Improves hardenability and aids in deoxidation.

- Silicon (Si): Approx. 0.50% Increases the steel's strength and elasticity.

Hardness

FAX-38 powder metallurgy steel is capable of outstanding hardness, typically ranging between 65−67 HRC (Rockwell Hardness). This range places it among premium steels and translates to the following for the user:

- Exceptional Edge Retention: Due to its high hardness and the combination of vanadium carbides, FAX-38 blades retain their sharpness for an incredibly long time, even with intensive use. Less frequent sharpening is needed. This property can be particularly appealing to chefs who demand maximum cutting performance and could find a place in Satake's premium line.

- Wear Resistance: The steel is extremely resistant to wear and deformation, ensuring a long lifespan for the blade.

- Challenging Sharpening: While its edge retention is excellent, the high hardness of FAX-38 might require more patience and appropriate equipment for sharpening. Diamond or ceramic sharpening stones, or professional sharpening systems, are recommended.

Durability and Performance

FAX-38's exceptional properties, derived from its powder metallurgy manufacturing and sophisticated alloy composition, lead to outstanding durability and performance in knife applications:

- Superior Edge Stability: The fine, uniformly distributed carbides, particularly the hard vanadium carbides, provide excellent edge stability. This means the cutting edge is less prone to micro-chipping or rolling, even during demanding tasks, maintaining its keenness longer.

- High Toughness for its Hardness: While exceptionally hard, FAX-38 is designed to offer a commendable level of toughness, especially when compared to other steels at similar hardness levels. The powder metallurgy process significantly reduces segregation and grain size, which mitigates the inherent brittleness that often accompanies extreme hardness. This balanced toughness ensures the blade can withstand impacts and lateral stresses without breaking or chipping, making it a reliable tool in demanding kitchen environments.

- Excellent Corrosion Resistance: With its high chromium content (approx. 15.00%), FAX-38 provides excellent resistance to rust and corrosion. This is a crucial feature for kitchen knives, as they are constantly exposed to moisture, acids from food, and various cleaning agents. This property ensures the blade remains hygienic and visually appealing over its lifespan.

- Long-Term Performance: The combination of extreme hardness, superior wear resistance, and good toughness means that knives made from FAX-38 will maintain their cutting performance and structural integrity for an extended period. This translates to a longer lifespan for the knife and consistent reliability for the user, even under professional use.

- Reliability for Premium Applications: FAX-38 is a prime example of a modern "super steel" that offers a compelling blend of attributes. Its ability to resist wear, hold an edge, and withstand stress makes it a top-tier choice for manufacturers like Satake when crafting high-performance, durable, and reliable premium kitchen knives that meet the exacting standards of professional chefs and discerning home cooks.

Application Areas – Satake Premium Knives

FAX-38 steel is typically found in premium, high-performance knives where edge retention and wear resistance are paramount:

- High-quality folding knives: Often used in the upper segment of EDC (Every Day Carry) knives, where users demand maximum edge retention and minimal maintenance.

- Premium hunting and outdoor knives: Durability and long-lasting sharpness facilitate fieldwork where sharpening options may be limited.

- Specialty kitchen knives: For knives that require the highest level of edge retention and precision, and which could find a place in professional kitchens or the collections of enthusiastic home cooks.

CLICK HERE TO ACCESS SATAKE FAX-38 POWDER METALLURGY STEEL KNIVES!